Purdue Asst Prof receives NSF funding for creating scalable bioplastic

Karthik Sankaranarayanan's team received a $7 million grant from the National Science Foundation.

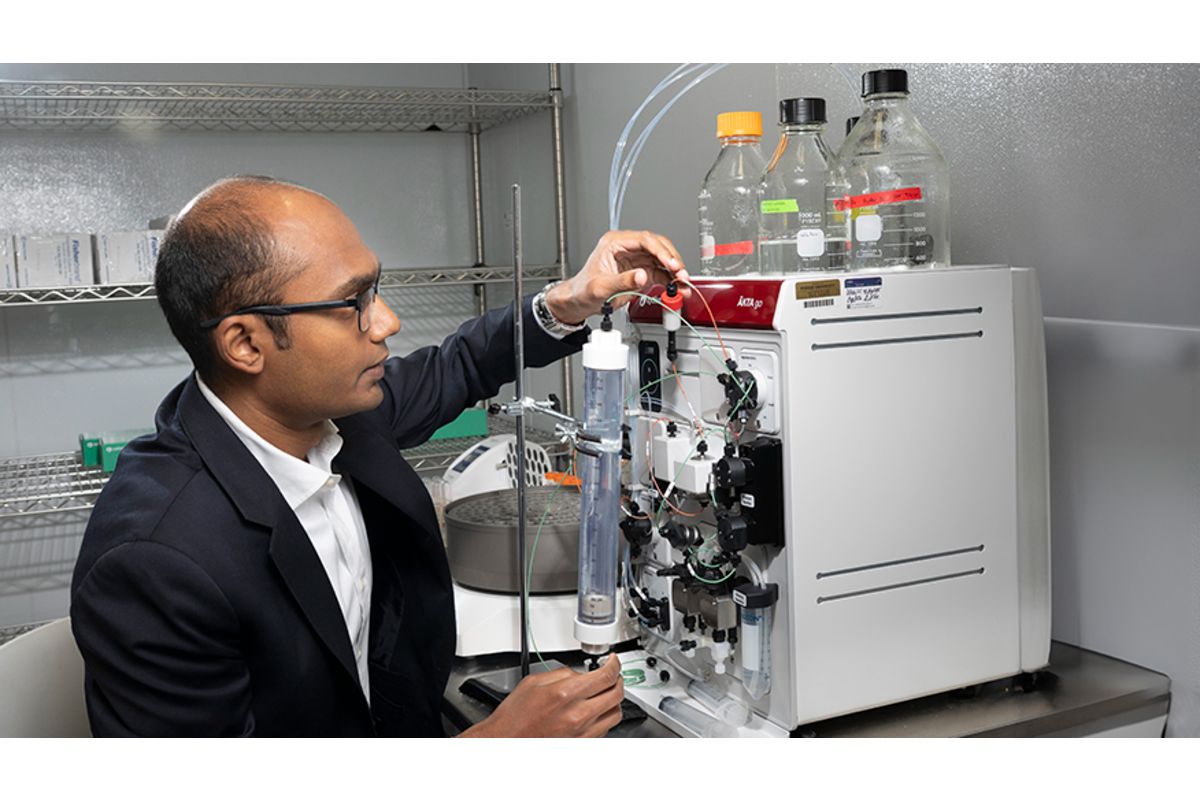

Karthik Sankaranarayanan operates a fast protein liquid chromatography system, which isolates and purifies proteins from a mixture. / Purdue University photo/John Underwood

Karthik Sankaranarayanan operates a fast protein liquid chromatography system, which isolates and purifies proteins from a mixture. / Purdue University photo/John Underwood

The U.S. National Science Foundation (NSF) has awarded Karthik Sankaranarayanan, from Purdue University, and his team to develop mechanisms to produce sturdy and reusable bioplastics.

Sankaranarayanan, an assistant professor of agricultural and biological engineering, along with his team, received a $7 million grant from NSF to design novel enzymes, a type of protein that speeds up chemical reactions, that convert various biomaterials into biodegradable plastics.

Research suggests that plastic production is a nearly $1 trillion industry, however, less than 10 percent of the produced plastic finds its way into recycling plants, the vast majority of the remainder gets either incinerated or ends up in landfills.

The researchers hope to develop a plastic-like material which will have similar levels of toughness and malleability to the types of plastics that currently dominate the market. However, rather than relying on petroleum-based chemicals to create non-biodegradable plastic, these new degradable bioplastics would be generated using domestically produced feedstocks such as corn, sugar or agricultural waste.

Targeting not just environmental sustainability, Sankaranarayanan told Purdue about the ability to localize production and said, “Nearly 99% of the plastics produced today are made from petrochemicals derived from oil or gas, which often must be imported from outside the United States,”

He told the institution, “We want to take advantage of locally available materials, such as those commonly used throughout the state of Indiana.”

He also highlighted the recyclability of the bio-plastic he hopes to create and said, "You can take these polymers and break them down into their individual units and reuse them again and again."

The primary focus of this three-year project is on biocatalysis. It involves using enzymes to speed up highly specific reactions that produce desired products without harsh chemicals or extreme conditions, making the production process more sustainable and efficient.

ALSO READ: Indian-origin researchers develop framework for context-aware robots

Once the enzymes are engineered by the Purdue team, it will be sent to researchers at Stanford University to test its functionality and then back to Purdue, where researchers will analyze the speed of their reactions as well as their ability to tune the chemical structure of the polymer. Finally, researchers at the University of California, Berkeley will determine their properties and commercialization potential, as well as how microorganisms can be engineered to scale up for biomanufacturing.

California-based Twist Bioscience will be collaborating with Sankaranarayanan's team in this endeavor, offering the technology that will enable researchers to engineer the necessary enzymes.

Emily Leproust, CEO and co-founder of Twist Biosciences addressed the collaboration, and told Purdue University, “Working with Purdue elucidates real-world applications of complex sequences, which allows Twist to further advance our ability to manufacture difficult and previously hard-to-make sequences at scale, turning what was once considered difficult into routine."

She added, “This project provides a powerful example of how innovation and partnership can expand the boundaries of discovery for multiple real-world applications.”

This project is funded by the NSF’s Directorate for Technology, Innovation and Partnerships through the Use-Inspired Acceleration of Protein Design initiative.

ADVERTISEMENT

ADVERTISEMENT

E Paper

Video

Jeffin T. Kaleekal

Jeffin T. Kaleekal

Comments

Start the conversation

Become a member of New India Abroad to start commenting.

Sign Up Now

Already have an account? Login